THE KILN

I was discouraged by the price and yet the seemingly simple design and operation of even the smallest kilns so I built my own!

I wanted to expand so I bought a hotter oxygen/propane torch, built a small kiln and set up a workbench in my apartment. This allowed to to make larger beads and expand into borosilicate glass to make marbles and pendants.

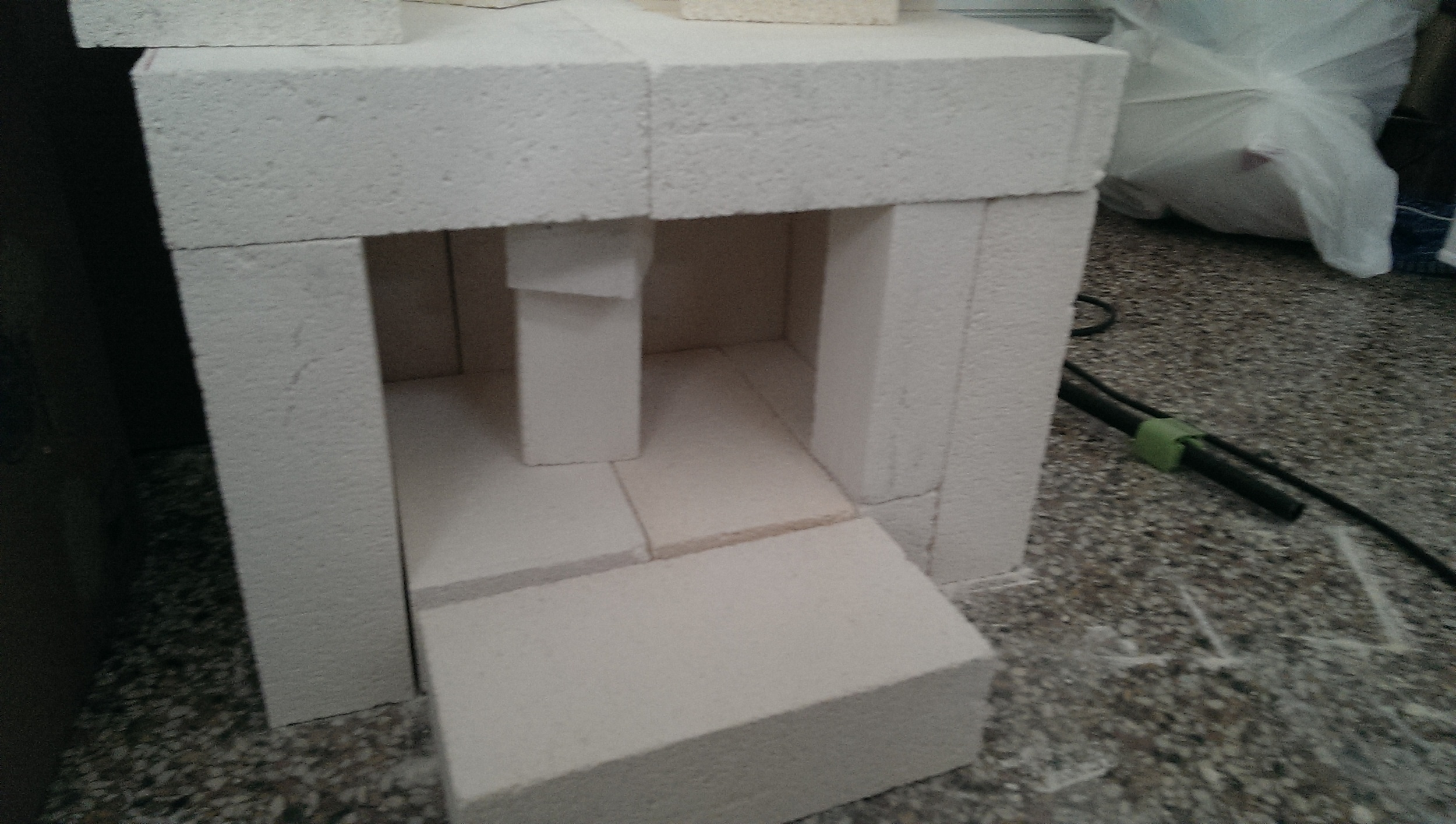

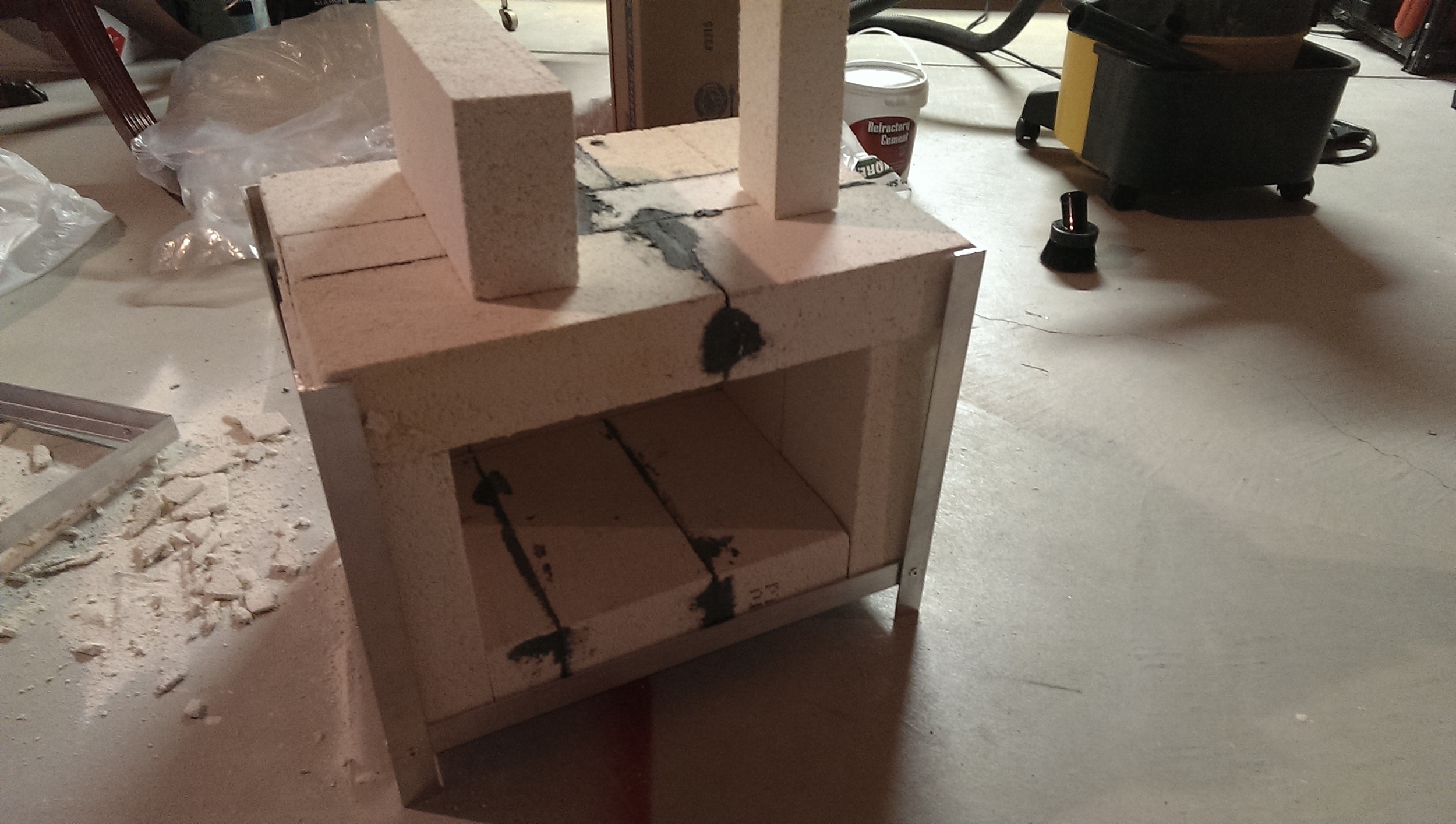

Here's a few pictures of the kiln.

Materials:

- 2300 degree firebrick

- 1" x 1" angle aluminum,

- 20 gauge aluminum sheet.

- Aluminum rivets.

- 1/4" threaded rod, washers and nuts to reinforce the roof

The total cost of the kiln was around $230.

It's not the prettiest but it worked well. I look forward to using it for more than just glass as well like burning out molds for lost wax casting and maybe small clay work If I can fire it to temperatures hot enough. I used a 9 amp kiln element made of kanthal wire designed for another kiln on the market of a similar size.

THE CONTROLLER

The controller was also built by myself with a PID temperature controller found on ebay, a K type thermocouple, and a 25 amp solid state relay. The project box was from RadioShack and the total cost was around $60. It doesn't have some of the features of other more expensive kiln controllers such as programmable ramp/soak and annealing settings but it can hold the temperature well and the PID controller can easily be upgraded in the future.